Precision Beyond Boundaries

ITALIAN MACHINERY EXCELLENCE

We are having an installed capacity of 7 million+ buttons per day. We use latest button manufacturing machines including Italian machinery from Bonetti, Tullio Giusi & Fabes and other ancillary and balancing Indian machines in manufacturing polyester buttons. We also make use of latest and advanced sheet casting drums for button making. Continuous research and innovation with new technologies is strongly emphasised. As such using the Laser technology for engraving names have placed on amongst the favorites list of many big clients.

In the realm of button manufacturing, Bonetti, Tullio Giusi & Fabes, along with cutting-edge Indian polyester button making machines, form a powerful alliance, contributing to the precision and excellence of the production process.

Bonetti: One of the latest button manufacturing machines is Bonetti. Renowned for its precision and reliability, Bonetti machinery is one of the important polyester button making machines and plays a crucial role in the initial stages of button production. This includes processes such as molding and shaping, ensuring consistent and high-quality button blanks.

Tullio Giusi & Fabes: Another renowned name in the polyester button making machines is of Tullio Giusi & Fabes. These Italian machines are integral to the intricate detailing and finishing stages of button manufacturing. Tullio Giusi specializes in intricate design work, while Fabes ensures impeccable polishing and surface finishing.

In conjunction with our Italian machinery, we leverage state-of-the-art ancillary machines from India. These latest button manufacturing machines contribute to the overall efficiency and precision of our manufacturing process, ensuring a seamless integration of technology.

HEAT PROOF DYEABLE BUTTONS

We are one of the largest manufacturers of polyester buttons in India!

With a installed capacity of manufacturing 7 Million+ buttons daily, we stand tall as a stalwart in the realm of button manufacturing.

Precision Innovation in Casting

SHEET CASTING DEPARTMENT

The Sheet Casting Department serves as the core of our manufacturing prowess, where precision meets innovation. Employing the latest button manufacturing machines, this department transforms raw materials into meticulously crafted sheets, laying the foundation for our diverse range of products. Our skilled technicians oversee every stage of the casting process, ensuring uniformity and quality. By combining expertise with Latest button manufacturing machines, we guarantee the production of high-performance sheets that meet stringent standards.

The Sheet Casting Department is further distinguished by its utilization of advanced sheet casting drums for button making, elevating our manufacturing capabilities. These specialized drums play a crucial role in shaping and solidifying the molten material, contributing to the creation of flawless sheets. With precision engineering and innovative design, these sheet casting drums for button making ensure a consistent and controlled casting process. This integration of sheet casting drums for button making underscores our commitment to cutting-edge latest button manufacturing machines, enhancing the overall efficiency and quality of our sheet production.

Precision Machining

MACHINING DEPARTMENT

The Machining Department boasts an array of latest button manufacturing machines specifically tailored for the intricate processes involved in button production. State-of-the-art CNC (Computer Numerical Control) machines take center stage, ensuring a level of precision that is paramount in crafting consistent and high-quality button blanks. These latest button manufacturing machines are programmed to execute complex tasks with meticulous accuracy, contributing to the uniformity and reliability of the final product. At the core of the Machining Department’s responsibilities is the mastery of molding and shaping processes. Here, raw polyester material undergoes a meticulous transformation, guided by precision polyester button making machines, to create button blanks that lay the foundation for the entire production line. The expertise within this department ensures that each button is not only aesthetically pleasing but also functionally sound.

PREMIUM FINISH

QUALITY CHECKED

SUPERIOR SHINE

Comprehensive Button Manufacturing Solutions

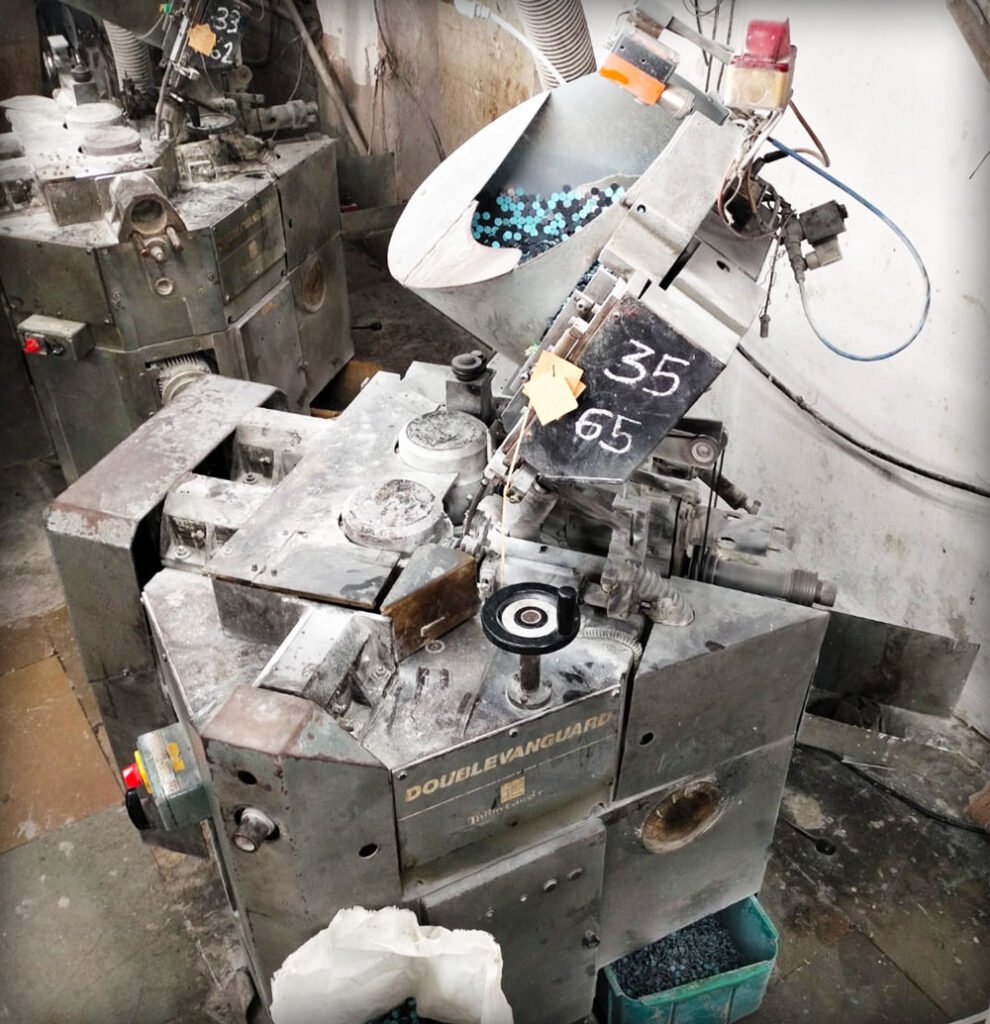

DOUBLE VANGUARD 4Th

DOUBLE VANGUARD 4TH is a polyester button making machine capable of manufacturing double side turned buttons. Fancy buttons with different attachments like P, I, C, E, A, S, M, etc can be fitted. Stroke adjustment for turning units provided on top of the machine. Capable of making up to 208 buttons a minute.

DOUBLE VANGUARD 3RD

DOUBLE VANGUARD 3RD Machines is a polyester button making machine capable of manufacturing double side turned buttons. Fancy buttons with different attachments like P, I, C, E, A, S, M, etc. can be fitted. Capable of making up to 208 buttons a minute.

FUTURA/MAXOMATIC

FUTURA is the latest button manufacturing machine which is single sided machine for high speed production with negligible maintenance. Versatile yet very economical in running. Specially designed machines for fancy button production with pre-fitted attachments like Index, Polygonal, Fish Eye and Vertical drill. Capable of making up to 200 buttons a minute.

Tool Sharpening

The Tool Sharpening machine in button manufacturing meticulously enhances cutting tool edges, ensuring precision and longevity. A crucial element in crafting quality buttons, it optimizes manufacturing efficiency.

Sheet Punching

Essential in polyester button manufacturing, it precisely punches sheets, creating button components with accuracy and efficiency.

Sheet Pouring

Crucial process, pouring sheets in polyester button production ensures uniformity and quality in the manufacturing of button blanks.

Profile Tool Making

Precision in button design is achieved through profile tool making, shaping the molds that form distinct button profiles.

Resin Mixing

The resin mixing machine blends materials, contributing to the durability and aesthetic appeal of polyester buttons in production.

Tool Making Cutter

This cutter refines molds for button production, ensuring intricate designs and maintaining precision in polyester button manufacturing.

Needle Sharpening

A vital process in polyester button production, needle sharpening ensures the precision and longevity of tools used in the manufacturing process.

ATTACHMENTS

With wide variety of attachments available one can source most of them used in Bonetti or Tullio Giusi machines from us. Be it P/E/R/F/FG/W/V/S/A/Y/K. Currently, laser being an expensive technology we believe why waste the laser when the same button can be manufactured with same accuracy and similar speeds with these attachments.

TULLIO GIUSI

Why waste your Precious Laser Gas if the same accuracy can be obtained from Company provided attachments with similar speeds. P/E/R/F/FG/W/V/S/A/Y/K

- P: Unit for polygonal cutting and turning. Oval, Triangle, Square, pentagonal hexagonal cutting and turning /can be done. Different gear settings coupled with tool centering on holder for concave or convex -turning/cutting for curved or sharp edges. Capable of producing 120 buttons a minute. P.S. Also can be used instead of ‘t’ when not using gears.

- E: Unit for Embossing /Engraving on buttons. Dies can be changed to have different embossing. Capable of producing 120 buttons a minute. Quality of dies used is important and can be used instead of laser. Additional requirement Compressed Air onto the attachment

- R: Unit for concave milling of shank buttons. To be mounted on the second head of the machine. Capable of producing 100 buttons a minute. Use of diamond cutters recommended instead of plain stone cutters or any other steel.

- F: Unit for Fish-eye, encoche, shank, channel shank and other millings. Can be mounted on ‘T’ units. To be mounted on the second head of the machine.

- FG: Unit for Fish-eye, encoche, shank. Can be mounted on ‘T’ units.

- W: Unit for vertical drilling. To be mounted on turning units on first or second head. Suitable for Costume jewelry like beads

- V: Unit for vertical drilling, primarily for shank and channel shank drilled buttons. To be mounted on drilling unit ‘d’

- S: Unit for Internal or external undercut turning

- A: Unit for slot milling single or simultaneously two slots can be milled. To be used with 2Hole/4hole drilling bushes.

- Y: Unit for round, axial and left inclined turnings. Can be inclined to the Left upto 15 degrees and also can be vertically adjusted upto 10 mm both up and down. To be mounted on Double Vanguard in position 1 or 3

- K: Unit for round, axial and Right inclined turnings. Can be inclined to the right upto 15 degrees and also can be vertically adjusted upto 10 mm both up and down. To be mounted on Double Vanguard in position 2 or 4

- I: Index; C: Contour; FE: Fish Eye; T: Unit for round turning; D: Unit for drilling 2/4 holes; Vertical Drill; ODS; Slot; Hard Rod Cutting

BONETTI

Polygonal (MPN), Hard Rod Cutting, Index, Fish Eye, Vertical Drill, etc. All Bonetti attachments can be fitted in TM Nova:

- M/PN: Polygonal

- FORG/N: Shank drilling

- FRG3/N: Fish Eye

- FRG1/N: Cutter

- LAM-I/N (Lamatture): 90Degrees Swinging Device allowing horizontal and vertical milling. Be it concave or convex, straight or wavy, it is suitable for all.

- Index Super: Unit for multiple concentric and excentric milling and turning designs

ANCILLIARY MACHINES

Different Size Mixers, Sheet Sampling Drum, Punching Dies, Punches, Punch Polish, Punch Aligner, and Centrifugal dryers.

Tool and Needle Grinder, Tool Profiler, Tool Maker, Blowers, Ductings, Polishing Drums of varied sizes, Inspection Machines etc.

[ FAQs ]

Frequently Asked Questions

Italian machinery such as Bonetti, Tullio Giusi & Fabes, along with cutting-edge Indian polyester button making machines, form the backbone of the production process at Classic Buttons Pvt. Ltd. These machines ensure precision and reliability, contributing to the excellence of our polyester button manufacturing. From molding and shaping to intricate detailing and finishing, our button manufacturing machines guarantee consistent and high-quality production.

Our Sheet Casting Department leverages advanced sheet casting drums for button making to elevate our manufacturing capabilities. These specialized drums shape and solidify molten material with precision, ensuring flawless sheets. By integrating these drums with the latest button manufacturing machines, we achieve a consistent and controlled casting process, guaranteeing the production of high-performance sheets that meet stringent standards.

Classic Buttons Pvt. Ltd.’s machining Department utilizes state-of-the-art turning machines, programmed for precision, to craft consistent and high-quality buttons. These machines execute complex tasks with meticulous accuracy, ensuring uniformity and reliability in the final product. Guided by precision polyester button making machines, raw polyester blanks undergo transformation into aesthetically pleasing and functionally sound buttons.

DOUBLE VANGUARD 4TH is a cutting-edge button manufacturing machine capable of manufacturing double-sided buttons. It offers versatility by accommodating fancy buttons with various attachments like P, I, C, E, A, S, M, etc. With stroke adjustment for turning units and a production capacity of up to 208 buttons per minute, it stands out for its speed and efficiency in button manufacturing.

The Tool Sharpening (button manufacturing) machine meticulously enhances cutting tool edges, optimizing manufacturing efficiency and ensuring precision in button production. By maintaining sharp and durable tools, these polyester button making machines contribute to the overall quality and longevity of the manufacturing process.

The Sheet Punching machine plays a vital role in polyester button manufacturing by precisely punching sheets, creating button blanks of the required sizes or Linge. Its capability for precise punching ensures uniformity and quality in the manufacturing of button blanks, laying the foundation for the entire production process. It is a vital polyester button making machine.

Needle Sharpening is a vital process in polyester button manufacturing as it ensures the precision and longevity of tools used in the production process. By maintaining sharp needles, this process optimizes manufacturing efficiency and accuracy, ensuring consistent and reliable button production. Classic Buttons Pvt. Ltd. consistently uses needle sharpening machines to ensure that the buttons producted, have proper holes.